An Innovative Solution

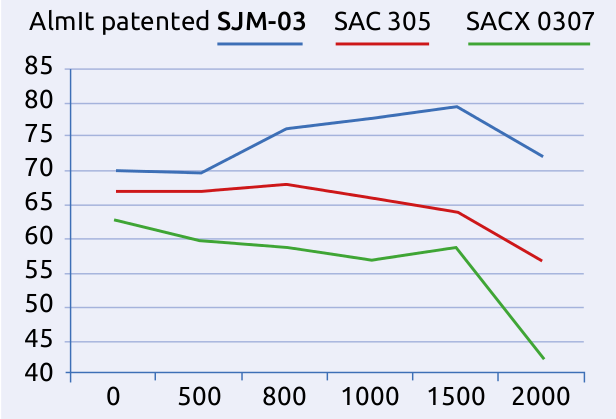

The soldering pastes and soldering wires in the SJM series are the results of extensive development work by the Almit research department. Whilst general lead-free alloys used up until now already begin to show cracks after 500 cycles, the patented SJM 03 for example even remains intact after 1,500 cycles and shows no cracks whatsoever.

With perfect strength

The SJM series delivers a new dimension in strength to lead-free alloys. And so the initial strength of SJM 03 compared to the usual SAC 305 alloy used shows an improvement of 6%.

The added metals and their advantages

- Bi (bismuth) increases the tensile strength and resistance to tearing, increases the long-term reliability.

- Fe (iron) minimises wear on the soldering tip

- Sb (antimony) ensures even better long-term reliability

- Ga (gallium): prevents oxidisation

The strength after 2,000 cycles can even be up to 33% higher. Even for a still higher strength there is an optimum solution:

SJM series lead-free alloys:

Silver content from 0.3% up to 4%.

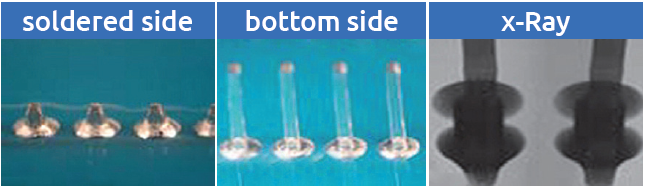

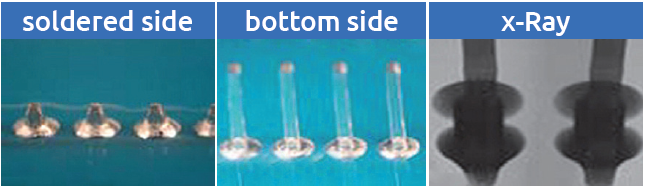

Ideal with through–hole contacts

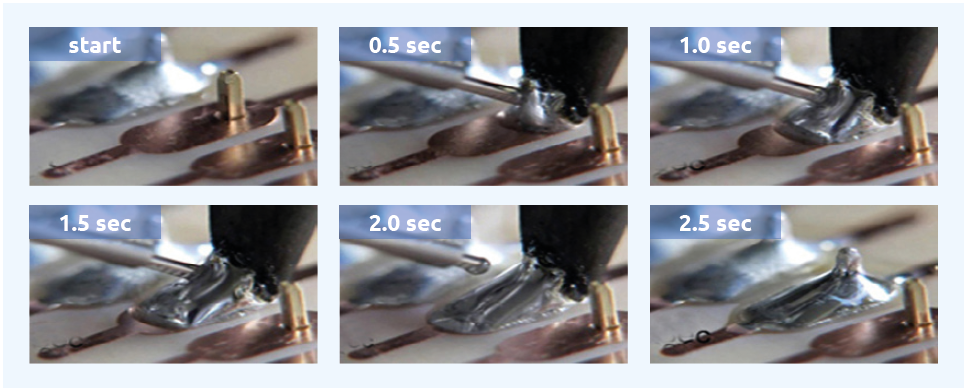

Characteristic for the SJM series alloys are the superlative wetting and working characteristics (RMA compliant). In this way they are ideally suited for soldering on through-hole circuit boards.

SJM series – ideal for through–hole circuit boards

The advantages of the SJM series at a glance

- lead-free

- no crack formation

- perfect strength

- a silver content of from 0.3% to 4%

- patented alloy

- ideal for through-hole soldering

What does SJM stand for?

"SJM" stands for high-strength alloys with particularly high strength. There is no crack formation when the solder joint hardens.

"SJM" steht für hochfeste Legierungen mit besonders hoher Festigkeit. Es kommt zu keiner Rissbildung bei der Aushärtung der Lötstelle.