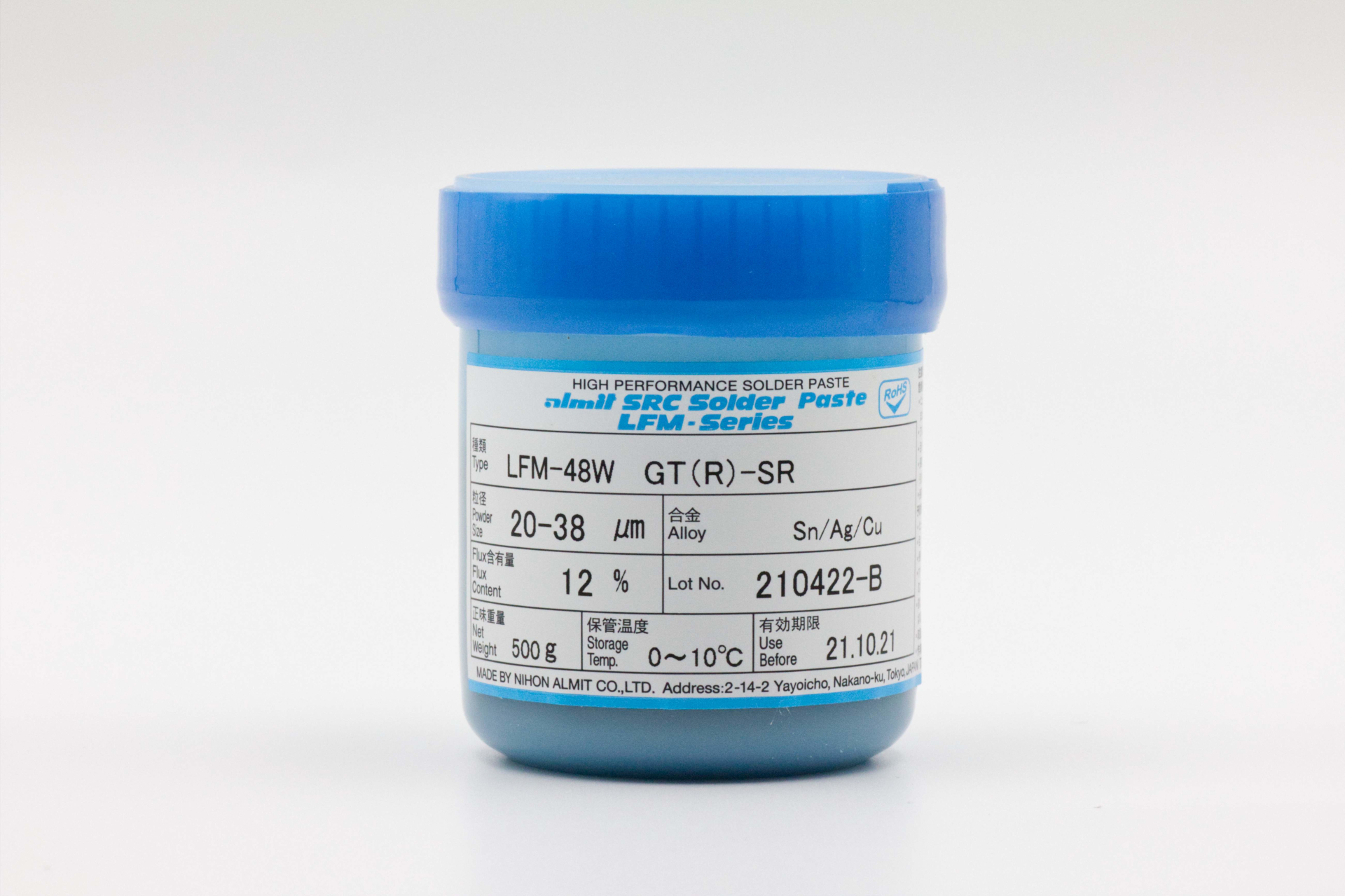

Perfect performance for the SMT-process

Do you think that soldering defects cannot be prevented in the SMT-process? This is just not true. Discover the GT solder paste. It guarantees optimum wetting on the most widely varied surface materials and keep high yield by minimising soldering defects.

Do you wish for an individual consultation? We are looking forward to hearing from you at technicalsupport@almit.de!

Short facts:

Amongst other materials suitable for copper, nickel, brass and phosphor-bronze

RoHS compliant

Special advantages

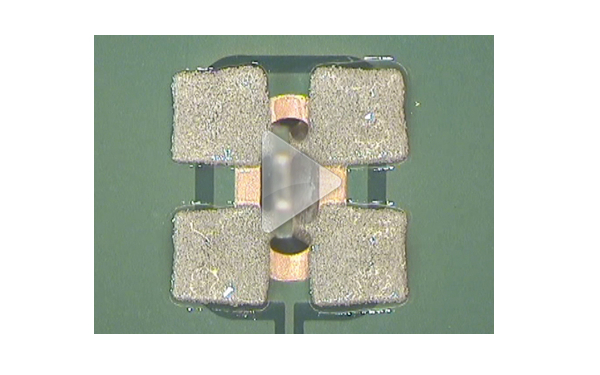

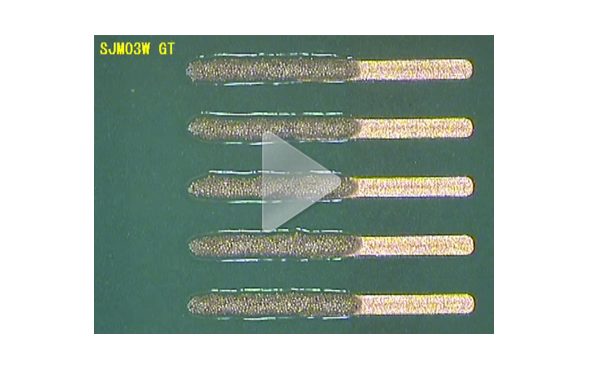

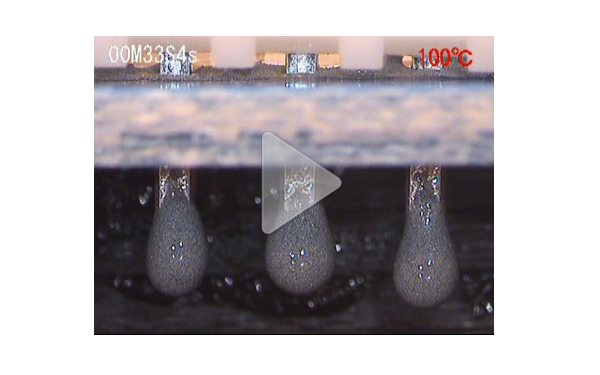

Optimum wetting

Very wide range of applications

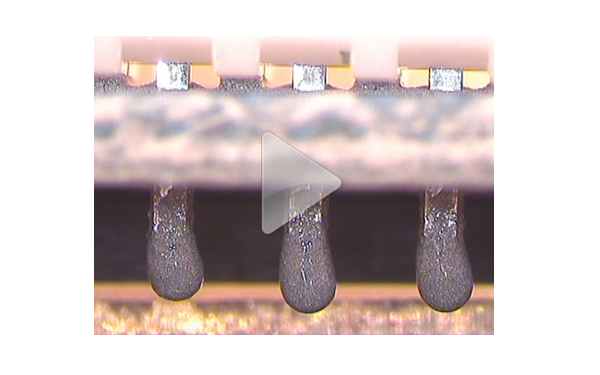

Designed for PIP/THR

Very good printing even on the smallest structures