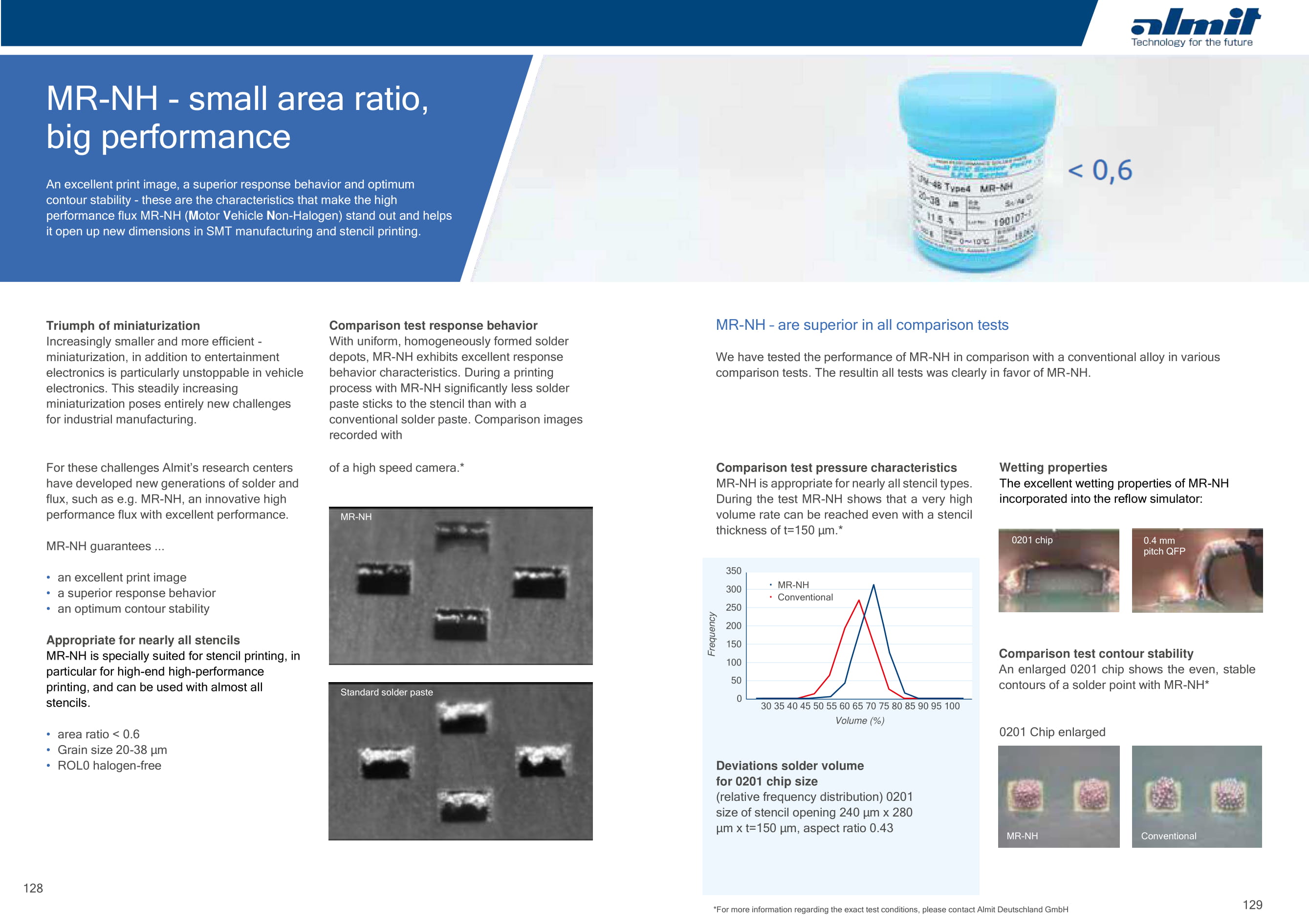

Small area ratio, big performance

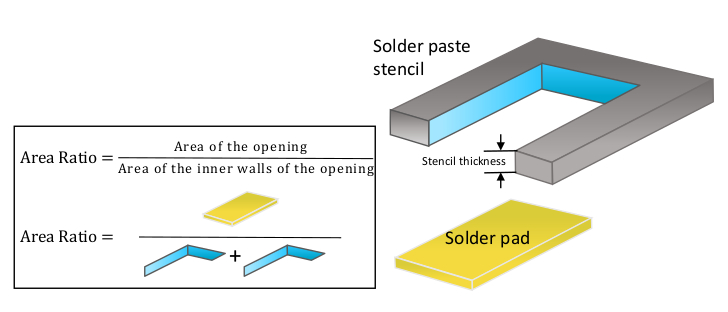

The constantly increasing miniaturization poses completely new challenges for industrial production. In order to meet these at eye level, we are developing new generations of soldering and fluxing agents in our Almit research centres. MR-NH is an innovative high-performance solder paste with an outstanding performance that opens up new dimensions in SMT production and stencil printing. Even in applications with an area ratio of less than 0.6, MR-NH convinces with perfect release properties, so that a step stencil is not required for a high component mix.

Do you wish for an individual consultation? We are looking forward to hearing from you at technicalsupport@almit.de!

Short facts

Area ratio < 0.6

Powder size 20-38 µm and 10-28 µm

ROL0 halogen-free

Special advantages

Excellent print image

Excellent release properties

Optimal contour stability

Applicable with almost all stencils

Shop now