Flux of lead-free solder pastes

| Flux |

Flux classification |

Particular advantage |

NH (LVA)

100% halide-free |

ROL0 |

reduces voids, improves printability |

| MR-NH |

ROL0 |

even appropriate for applications with an area ratio smaller than 0.6 |

NH(-MDL)

100% halide-free |

ROL0 |

micro dispensing |

NH (IMT)

100% halide-free |

ROL0 |

characteristics like L1 paste, still perfect after long open time |

| INP |

ROL1 |

designed for indium based alloys |

| GT-Serie |

ROL1 |

high preheat resistance, perfect print shape |

| SUC-Serie |

ROL1 |

O2-reflow, low voiding |

| PZV |

ROL1 |

perfect for low peak temperatures |

| HF-A |

ROL0 |

laser applications |

| MDA-5 |

ROL1 |

jet printing paste for MYDATA U |

| MJD |

ROL1 |

jet printing paste for Musashi R5-20 |

| SSI-M |

ROM1 |

laser application |

| TM-HP (O) |

ROM1 |

long open time |

| SBR |

ROL1 |

ideal for bismuth alloys |

Lead-free solder paste alloys at a glance

| Alloy |

Composition |

Melting range |

Particular advantage |

| LFM-65 |

Sn-58.0Bi |

139°C |

very low melting range, Sn-Bi eutectic |

| LFM-89 |

Sn-57.6Bi-0.4Ag |

139–168°C |

very low melting bismuth alloys with increased strength |

| LFM-78 |

Sn-57.0Bi-1.0Ag |

139–179°C |

very low melting bismuth alloys with increased strength |

| LFM-31 |

Sn-8.0Zn-3.0Bi |

190–203°C |

also usable with temperature profile of Sn-Pb alloys |

| LFM-70 |

Sn-3.5Ag-0.5Bi-8.0In |

194– 206°C |

low melting range, SABI |

| LFM-96 |

Sn-3.5Ag-0.5Bi-6.0In |

202–210°C |

low melting range, SABI |

| SJM-03 |

Sn-0.3Ag-0.7Cu-2.0Bi-α |

210–225°C |

low Ag, high solder joint strength |

| LFM-90 |

Sn-1.0Ag-0.7Cu |

217–224°C |

JEITA recommended |

| LFM-48 |

Sn-3.0Ag-0.5Cu |

217–220°C |

SAC, JEITA recommended |

| LFM-86 |

Sn-0.3Ag-0.7Cu |

217–228°C |

low Ag, SAC |

| LFM-34 |

Sn-3.5Ag eutectic |

221°C |

Sn-Ag |

| SJM-40* |

Sn-4.0Ag-2.0Bi-3.0Sb-α |

221–227°C |

high Ag, very high solder joint strength |

| LFM-57 |

Sn-5.0Sb |

235–240°C |

high melting range |

| LFM-74 |

Sn-10.0Sb |

246–258°C |

high melting range, Sn-Sb |

Powder size: X, W, U, N

All our lead-free solder pastes are available with the following flux content: 11-14%

*SJM-40 is patented under: JP PAT Nr. 3045453

SJM = Strong Joint Metal

LFM = Leadfree Metal

Favored product combinations for Almit solder pastes

| Alloy |

Flux classification |

Laser & inductive soldering |

Reflow soldering (SMT) |

LFM-48

(SAC 305) |

L0 |

HF-A

NH-MDL |

MR-NH |

| L1 |

SSI-M |

GT-Series |

| M1 |

- |

TM-HP(O) |

SJM-Series

(Sn, Ag, Cu, Bi) |

L0 |

- |

NH(IMT) |

| L1 |

- |

GT-Series |

| M1 |

- |

TM-HP(O) |

| LFM-96 |

L1 |

- |

INP |

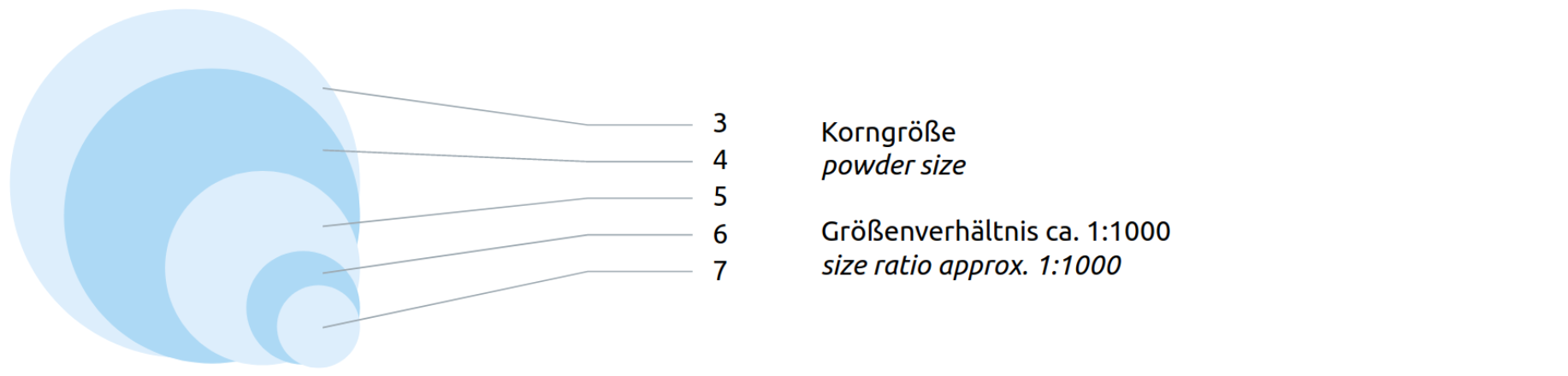

Crain size (µm) according to IPC

| powder size |

10% max. less than |

80% min. between |

10% max. between |

less than 0,5% larger than |

| 3 |

25 |

25 - 45 |

45 - 60 |

60 |

| 4 |

20 |

20 - 38 |

38 - 50 |

50 |

| 5 |

15 |

15 - 25 |

25 - 40 |

40 |

| 6 |

5 |

5 - 15 |

15 |

25 |

| 7 |

2 |

2 - 11 |

11 |

15 |

Almit powder sizes according to J-STD 005

| Almit name |

X |

W |

U |

N |

R |

G |

| Crain size in μm |

25-45 |

20-38 |

10-28 |

10-24 |

5-20 |

5-15 |

| Powder size |

3 |

4 |

5 |

5/6 |

5.5 |

6 |